Straight talk about the Japanese nuclear plant disaster

Read related article by David Spiegelhalter Professor of the Public Understanding of Risk, Cambridge University

By Ernest J. Harkness

For PlanPhilly

I am overwhelmed by the response to my commentary piece posted to PlanPhilly on March 17. I have spent my career operating nuclear power plants and still provide consulting services in the form of operational safety reviews and assessments. The following comments about the situation at the Fukushima-Daiichi Nuclear plant may help PlanPhilly readers understand the current and future issues there.

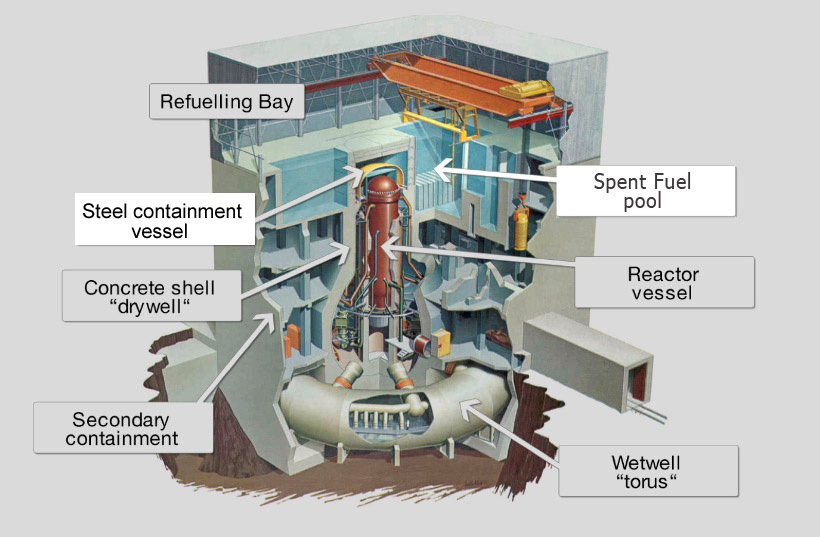

First a quick refresher on the plant configuration, of which I am intimately familiar. The Japanese plants use Boiling Water Reactors (BWR), which is a type of design that does not require generators to produce steam. Instead the steam is generated in the reactor vessel. The nuclear reaction heats water in the reactor vessel and the vapor from the water is passed through steam dryers to the turbines. This eliminates an additional fluid loop and provides some differences to other designs types.

This design is used around the world, including the United States, and has a proven good operating record. A reactor of this design has three barriers to contain the nuclear fuel and decay products. The actual fuel tube (an approximate 3/8” tube that contains the Uranium Oxide fuel pellet), the primary coolant loop and reactor vessel, and the primary containment.

The reactor building, in which the primary containment is housed, is sometimes called Secondary Containment and in U.S. plants this Secondary Containment is required by law for BWR type reactors.

The Spent Fuel Pool is where expired fuel is stored until final disposition or recovery. The Spent Fuel Pool is normally a concrete structure housed in the Secondary Containment structure and is a robust structure made of cement and steel in the form of a pool with the fuel stored under at least 20 feet of water.

Several units at Fukushima were off line and de-fueled at the time of the earthquake and three of the units were operating. The operating units shut down at the time of the earthquake. When a nuclear plant shuts down the chain reaction stops and the remaining heat is generated by the radioactive decay of the nuclear fission products.

The situation in Japan is very serious. The International Nuclear and Radiological Event Scale (INES) is a system developed and used by the International Atomic Energy Agency (IAEA) to rate events at nuclear powered facilities. It has rated Units 1, 2, and 3 as level 5 and Unit 4 at level 4. Level 5 is an accident with wider consequences and Level 4 is an accident with local consequences. The Three Mile Island accident was a level 5 and Chernobyl was rated level 7. There was no radiation dose to the public or any impact to the public due to the Three Mile Island Accident, however the impact to the plant and subsequent impact on the nuclear industry was significant from a financial and operational impact. A very good update on the Japan situation is provided by the IAEA here.

As of this morning, Sunday 3/20, it appears that the operators are gaining ground and bringing control to the Units. The operators have done a very heroic job in maintaining constant action to provide forward progress. After several days of monitoring the incident I am still astounded by the amount of sensational type reporting seen across the board by many media outlets.

I know many readers are not familiar with the technical details, which is expected, so I want to try to put some perspective to what is provided in the IAEA update.

The radiation levels were significant at times during the event. The difference between radiation and contamination is important. Radiation occurs when emitted from a source (such as exposed fuel rods, or an radioactive source in an x-ray). When the source is covered such as with water or lead shield, the is radiation reduced by the reduction factor of the material. For example, 24” of water or 2” of lead reduces the radiation level by 1/10th. Therefore a source of 100 mrem is reduced to 10 mrem when 24” of water or 2” of lead is place over the source. This is why Japan operators are attempting to add water. In addition to cooling, which is the primary driver, the water also reduces the dose from the source.

Contamination is different.

Contamination in simple terms is a radioactive source, such as radioactive iodine or a piece of radioactive material that is not where it is supposed to be, such as in the soil. In order to remove the contamination the source must be removed.

The Japanese operators are monitoring the food sources because any radioactive products such as Iodine can enter the food chain through the soil. On a side note, the reason Potassium Iodide pills (KI Pills) are distributed is because the human thyroid retains Iodide and the pills are taken to saturate your thyroid with non radioactive iodine which blocks radioactive iodine because the thyroid has been satisfied with the non radioactive iodine. Radioactive iodine in the thyroid increases the internal exposure or dose to the individual. The radioactive iodine decays to normal levels in a few weeks.

The possibility of radiation from the Japanese plants becoming a problem outside of Japan are minimal at this time. The appropriate authorities are checking products imported to the U.S. and this should be sufficient.

The Nuclear Regulatory Commission (NRC) has issued an Informational Notice 2011-05 to the US Nuclear Industry that requires all license holders (power plants) that operate a nuclear fueled plant to take actions to review the plant design based on what is currently known at this time from the events unfolding in Japan.

An interesting note is that after the 9/11 terrorist attack, the NRC required U.S. plants to prepare for a “beyond design bases” event initiated by terrorist activity. The preparations completed by the U.S. Industry were very robust and would apply to a event similar to the Japanese event. The U.S. industry has learned significant lessons and taken responsible action to ensure that the health and safety of the public is preserved with regard to nuclear fueled power plants.

It would be difficult to end this update without acknowledging the efforts of the Japanese people, the response by the world community, and the financial and technical support provided to our brothers in need. The Japanese have a lot in front of them and we must continue to maintain them in our thoughts and prayers.

Contact the writer at ejharkness@ejharkness.com

Ernest J. Harkness, is a power generation executive who for 35 years has managed large power generation facilities through a state of change, while ensuring the best performance is delivered in a safe and responsible environment that achieves individual respect. His industry roles have included:

- Site Vice President and Plant Manager for nuclear power plant operation including fiscal responsibility for $70M Operation and Maintenance and $20M Capitol budgets.

- Safety Review Board Sub Committee Chairman for Nuclear Utility fleet of nine Nuclear Power Plants in USA. Sub Committee is responsible for oversight of Quality Assurance Program, Security Program, Site Emergency Response Organization including interface with State, Local and Federal agencies.

- Responsible for implementation of performance based operational assessment program for a United Sates Utility Fleet and a Nuclear Facility in Canada, which includes program development, training of staff, and mentoring leadership from Vice President Nuclear Oversight and Regulator Affairs to members of the department staff.

- Military experience included the USN Naval Nuclear Power Program as a Mechanical Operator and ships diver stationed on the USS Parche SSN 683 and part of Submarine Development Group.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.