SEPTA’s green garage achieves environmental certification

I’m willing to bet that SEPTA’s Berridge Bus Shop in North Philly is one of the cleanest garages in the city, and thanks to environmental certification that the shop recently received, it is probably safe to bet that it is one of the greenest garages in the city, too.

This week SEPTA announced that its Environmental and Sustainability Management System (ESMS) at Berridge Bus Overhaul Facility and Print Shop achieved ISO 14001:2004 certification, making it one of just eight transit agencies in the country to comply with environmental standards set by the International Organization of Standardization.

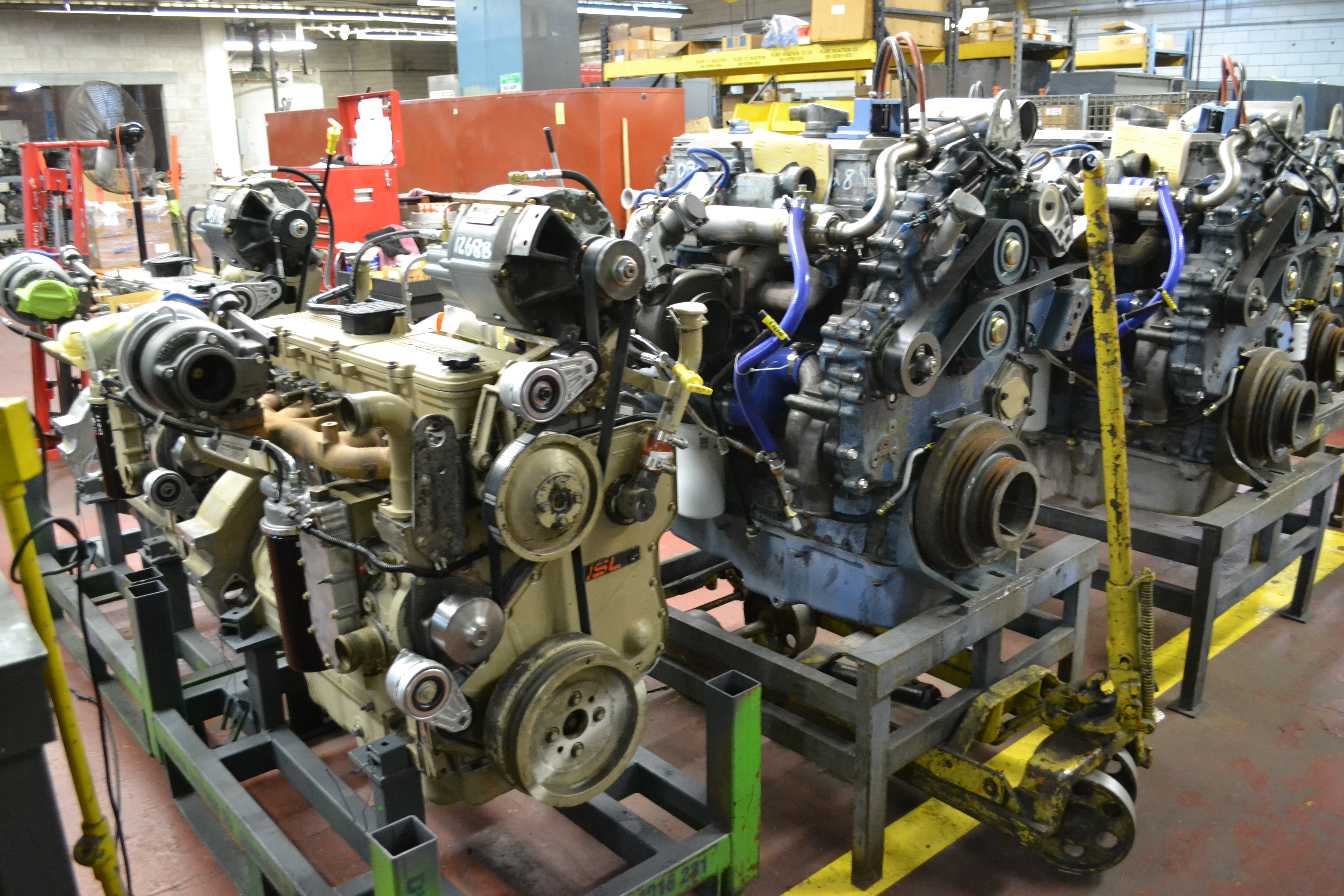

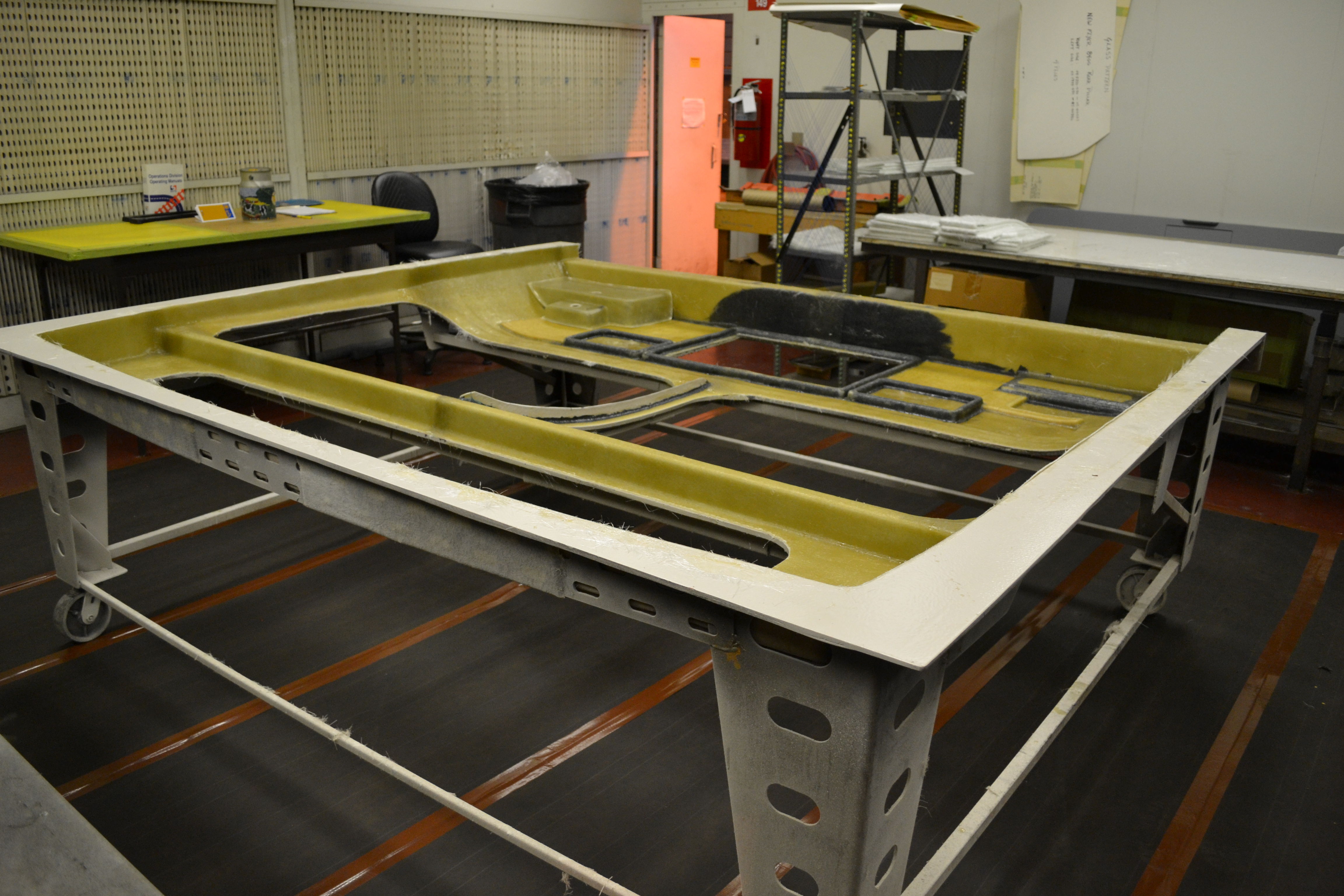

The Berridge Shop is located at SEPTA’s former headquarters at 2nd and Wyoming Avenues in North Philly. Even on a gray day, the shop is clean and bright – so clean that you notice the floor is painted red and not splotched and stained like a typical garage. In this facility, each and every SEPTA bus gets overhauled – completely gutted, cleaned, rebuilt and put back together. The work is divided and neatly spread throughout the shop, where all at once employees rebuild transmissions, test rebuilt engines, fabricate the front of a bus out of fiberglass and prep another bus for a fresh coat of paint.

The shop overhauls about 140 buses per year, and for each bus the process takes about six weeks, or 900 labor hours divided among the shop’s 167 employees. When they leave Berridge, even five and 10-year-old buses look and drive like new, said Fil Tosto, assistant director of maintenance at the shop.

While the shop was always well maintained, SEPTA made significant improvements to minimize the shop’s environmental impact and improve on-site safety in order to qualify for ISO certification.

One of the biggest changes is the way the shop stores and disposes of hazardous material – essentially any chemical used in the bus overhaul process. New, yellow spill stations are located throughout the garage, and the teams have been educated on how to use them. Recycling and waste bins are clearly labeled so employees know where waste oil and waste acetone go, where aerosol canisters go before they are drained, crushed and recycled, even where old fluorescent light bulbs and standard batteries go.

Anything and everything that can be reused is recycled. SEPTA switched to less harmful alternatives for cleaning agents and other chemicals, and shop managers adjusted waste collection schedules so that hazardous material is picked up more frequently. This means fewer hazardous chemicals are stored on site at any given time.

“One of the goals was to put the employees in the position where they are least likely to fail,” said Scott Sauer, SEPTA’s director of system safety and risk management. “We want to give the employees all the info they need so they don’t make a mistake.”

SEPTA also re-considered the shop’s impact on the city’s water.

“Our stormwater management runoff, we made sure there is no potential hazard there,” Tosto said.

Outside, bus engines that used to be heaped in a corner are neatly docked on shelves, and clear plastic wrap prevents rain from washing any oil or chemicals off of the engines and onto the ground. A 50-gallon drum crusher that used to be parked outside has been moved inside, where any leftover oil that seeps out of the crushed drums can be contained rather than washing away with stormwater. One piece of equipment inside the shop had been spewing oil onto the roof. Before the ISO process, shop managers did not think about that oil washing into the city’s water supply. Thanks to ISO, that equipment is no longer in use.

Another big change is the level of organization that SEPTA managers adopted as part of the ISO process. Everything in the shop has a dedicated place, especially hazardous materials and waste products. Old radiators used to be stripped from buses and tossed in a pile, only partially covered by a lean-to type roof. Now they are neatly stacked and organized by manufacturer on palates designed to catch any chemical drips.

Sauer said making these changes and attaining ISO certification was both a very intense process and a learning process. He said the goal was not to change the work at the shop but to reduce the environmental impact of that work, especially given the shop’s location.

“It’s a residential location, so we have to be a good neighbor,” he said.

Employees were onboard with the changes, and when asked why they supported the adjustment many brought up their grandkids. Manuel McDonnell Smith, SEPTA’s public information manager, said there was sense that the changes were not only for the employees, who will certainly benefit from a safer work environment, but for future generations.

“Everybody bought into it,” Tosto said. “They felt part of it … Whenever you’re talking about the environment or sustainability, they’re into it.”

This is just the beginning. Now that SEPTA knows how to execute shop changes that reduce environmental impact, the authority is ready to implement elements of the program at its other facilities.

“We’re continually improving,” said Martin Brunges, environmental manager for SEPTA’s system safety and risk management department. “We’re not stopping … It’s all about maintaining what we have now and improving.”

The Wayne Electric Car Shop, which services regional rail, and a utility shop that services light duty and maintenance vehicles, will get the full ISO treatment, “the full monty,” Sauer said. Another eight maintenance shops will see ISO-inspired improvements.

For SEPTA, meeting ISO standards makes good business sense. It helps the authority meet other regulatory benchmarks and makes SEPTA a stronger candidate for federal and grant funding. Plus with energy and water usage creeping down, reduced waste removal costs and revenue from increased recycling, going green has SEPTA seeing green.

“We’re seeing a dollar value that’s kind of been a reward for going in this direction,” Sauer said. “It is the environmentally conscious thing to do, the socially conscious thing to do, but it’s a good business decision.”

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.